41 Terms

41 TermsHome > Industry/Domain > Manufacturing > Plastic injection molding

Plastic injection molding

Plastic injection molding is the primary process for manufacturing plastic parts used in consumer goods such as computer keyboards, monitors, bottle caps, cups and solid plastic articles. Plastic is known to be a very versatile and economical material that is used in many applications. Injection molding involves taking plastic in the form of pellets or granules and heating this material until a melt is obtained. Then the melt is forced into a split-die chamber/mold where it is allowed to "cool" into the desired shape. The mold is then opened and the part is ejected, at which time the cycle is repeated.

Industry: Manufacturing

Add a new termContributors in Plastic injection molding

Plastic injection molding

vetolujuus

Manufacturing; Plastic injection molding

Suurin vetolujuus aiheutuneen yksilö jännitteitä testin aikana

taivutus kimmokerroin

Manufacturing; Plastic injection molding

Suhde elastinen rajoissa näytteen taipeet vastaava kanta yksilö syrjäisimpien osia sovelletaan stressiä.

kuivaus

Manufacturing; Plastic injection molding

Altistuminen tietyissä aika ja lämpötila hartsin pelletit kosteuden poisto. Kaikki Hydroscopic materiaali on kuivattava ennen laudaksi.

kovuus

Manufacturing; Plastic injection molding

Materiaali pakkaus, sisennys ja naarmuuntumisen kestävyys.

ominaispaino

Manufacturing; Plastic injection molding

Suhde materiaali verrattuna veden normaali ilmanpaine tiheys tiheys (1 ATM) ja huoneen lämpötila (73F).

Modulus taipeet

Manufacturing; Plastic injection molding

Suhde taipeet stressin kanta materiaali joustava rajoissa.

suurin tekijä

Manufacturing; Plastic injection molding

Kaikki tietyn massan irti muovia materiaalin määrä sama massa materiaalia jälkeen laudaksi tilavuuden suhdetta.

Featured blossaries

zblagojevic

0

Terms

5

Blossaries

2

Followers

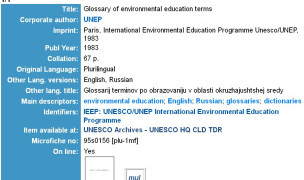

Glossary of environmental education

41 Terms

41 Terms